pneumatic comparator and solex pneumatic comparator

Principle of pneumatic comparator

- The measurement is made by taking reading using master gauge of known accuracy and comparing with component reading

- It uses a controlled, pressurised jet of air to measure small dimensional variation in the size of component

- The working principle of pneumatic comparator depends on the flow of air between the gauge head and the component being checked

Important characteristics

- Very high magnifications are possible

- It can be used to measure diameters, length, squareness, parallelisms, concentricity,taper, and other geometric conditions.

- Internal dimensions can be readily measured , in other words, while measuring a bore it can reveal complete details of size, taper, straightness,camber and bell mouth etc.

- It is independent of the operator skill

- High pressure air gauging can be done by cleaning the parts which helps to eliminate errors due to dirt and foreign matter.

- As there is no physical contact made either with the setting gauge (or) the part being measured , there is no loss of accuracy because of gear wear.

- Gauging pressures can be kept sufficiently low to prevent part deflection

- Dimensional variations throughout the length of the shaft (or) cylinder bore can be explored for out of roundness, taperness, concentricity,regularity and other similar conditions

- The total life cost of the gauging heads is much less

- It is accurate, flexible, reliable,universal and speedy device for inspecting parts in mass production

- It is best suited for checking multiple dimensions and conditions on a part simultaneously in least possible time.

- It can be easily used for a line measurement of parts as they are being machined and take corrective actions.

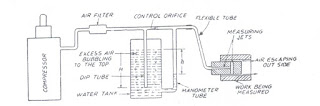

Principle of Solex Pneumatic Comparator

Working principle of Solex pneumatic comparator

- This instrument is produced commercially by Solex air gauges Ltd.

- This is generally designed for internal measurement

- But with suitable measuring head it can be used for external gauging also

- The arrangement used in Solex gauge is to pass the high pressure air after filtering through a flow valve

- It consists of a tank in which water is filled up to a certain level and dip tube is immersed into it up to a depth corresponding to air pressure .

- In the Fig it is represented by `H`

- Air is sent at higher pressure than required one

- Some air will leak out from the dip tube and bubble out of water

- And the air moving towards control orifice will be at desired constant pressure `H`

- It is very obvious from Fig that the diameter being measured at any instant is corresponding to the portion against two jets

- To find the concentricity (roundness of any job at any section) The work piece may be revolved around the measuring gauge

- Similarly the diameter can be noted down at several places along the length of bore and thus tapering of hole is determined

- This method is best suited for measuring roundness and taperness of cylinder bores and gun barrel bores

- By having suitable measuring head this can be used for external gauging also

Advantages of Pneumatic Comparators

- Comparators can be checked with out contact with finished surfaces

- This method needs little skill to operate

- No limit to the size of work that can be tested

- Provide a simple and direct method of high amplifications

- Dimensional variations can be controlled with close tolerances

By Lecturer B.Ravikumar Mechanical Engineering

Boutique spécialisée dans les pièces Solex comme pneu pour VéloSolex 3800, joints, Cylindre, Piston, pompe à essence. Stock pour Solex à prix raisonnable!

ReplyDeletepiece solex