Measurement of Engineering Components

Gauges are used mainly to check the Engineering Components produced on mass scale, where the job is usually handled by semi-skilled workers. This type of measurement cannot be relied upon where accuracy is more important. The different methods and instruments used for precision & accurate (linear & angular) measurements are discussed in this unit.

Comparator

It is a precision instrument employed to compare the dimension of a given component with a working standard (generally slip gauges). It does not measure the actual dimension but indicates how much it differs from the basic dimension (working standard).

Uses of Comparator :

- For calibrating the working gauges

- Used as working gauges

- Used as final inspection gauges

Essential characteristics of a good Comparator :

- Robust design and construction

- Linear chara cteristics of scale

- High magnification

- Quick in results

- Versatility

- Minimum wear of contact point

- Free from back lash

- Quick insertion of work piece

- Provision for compensation from temperature effects

- Provision for means to prevent damage du ring use.

Classification of comparators

1) Mechanical comparator

a) Dial indicator

b) Johansson Mikrokator comparator

c) Sigma comparator

d) Reed type mechanical comparator 2) Optical comparator

a) Zeiss Ultra optimeter

b) Zeiss optotest comparator

3) Mechanical – Optical comparator

4) Electrical comparator

5) Fluid displacement comparator

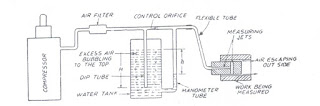

6) Pneumatic comparator a) Back pressure comparator

b) Flow – velocity Pneumatic comparator In addition, the comparators used in standards room for calibration of gauges are :

7) Brookes Level comparator

8) Eden-Rolt Millionth Comparator

Basic principle of operation of comparator

The comparator is first adjusted to zero on its dial or recording device with a gauge block in position. The gauge block (slip gauges) is of dimension which the work piece should have. The work piece to be checked is then placed in position and the comparator gives the difference in dimension in relation to the gauge block. The dimension of the work piece may be less than, equal to, or greater than the standard dimension. The difference in the dimension will be shown in the dial or in the recording device of the comparator.

Mechanical Comparators: Various mechanical comparators are discussed next.

Dial indicator

It is the simplest type of mechanical comparator. It consists of a base with a rigid column and an arm carrying dial gauge (dial indicator). The arm can be adjusted vertically up and down along the column. The arm can be swivelled and the dial gauge also can be locked in any position along its arm. The whole set up is placed on the surface place which is used as a datum surface.

uses, characteristics and classification of a comparator.

(i) Uses of Comparator

The various ways in which comparators can be used are:

1. Laboratory Standards: Comparators are used

as laboratory standards from which working or inspection gauges are sent and corelated.

2. Working Gauges: They are also used as working gauges to prevent work spoilage and to maintain required tolerance at all important stages of manufacture.

3. Final Inspection Gauges: Comparators may be used as final inspection gauges where selective assembly, of production parts is necessary.

4. Receiving Inspection Gauges: As receiving inspection gauges comparators are used for checking parts received from outside sources.

5. For checking newly purchased gauges: The use of comparators enables the checking of the parts (components in mass production at a very fast rate)

(ii) Essential characteristics of a good comparator

1. Robust design and construction: The design and construction of the comparator should be robust so that it can withstand the effects of ordinary uses without affecting its measuring accuracy.

2. Linear characteristics of scale: Recording or measuring scale should be linear and uniform (straight line characteristic) and its indications should be clear.

3. High magnification: The magnification of the comparator should be such that a smallest deviation in size of components can be easily detected.

4. Quick in results: The indicating system should be such that the readings are obtained in least possible time.

5. Versatility: Instruments should be designed that it can be used for wide range of measurements.

6. Minimum wear of contact point. The measuring plunger should have hardened steel contact or diamond to minimize wear effects. Further the contact pressure should be low and uniform.

7. Free from oscillations: The pointer should come rapidly to rest and should be free from oscillations.

8. Free from back lash: System should be free from back lash and unnecessary friction and it should have minimum inertia.

9. Quick insertion of workpiece: Means should be provided for lifting the plunger for quick insertion of work.

10. Adjustable Table: The table of the instrument should, preferably, be adjustable in a vertical sense.

11. Compensation from temperature effects: The indicator should be provided with maximum compensation for temperature effects.

12. Means to prevent damage: Suitable means should be provided for preventing damage of the instrument in the event of the plunger moving through a greater distance than that corresponding to the range of its measuring scale.

(iii) Classification

A wide variety of comparators are commercially available at present. They are classified according to the method used for amplifying and recording the variations measured into the following types.

1. Mechanical comparators

2. Optical comparators

3. Mechanical-Optical comparators

4. Electrical and Electronics comparators

5. Pneumatic comparators

6. Fluid displacement comparators

7. Projection comparators.

8. Multi check comparators

9. Automatic Gauging Machines 10. Electro-Mech. Comparators.

In addition to above, comparators of particularly high sensitivity and magnification, used in standard rooms for calibration of gauge include.

1. The Brookes Level comparator

2. The Eden-Rolt millionth comparator.

Comments

Post a Comment